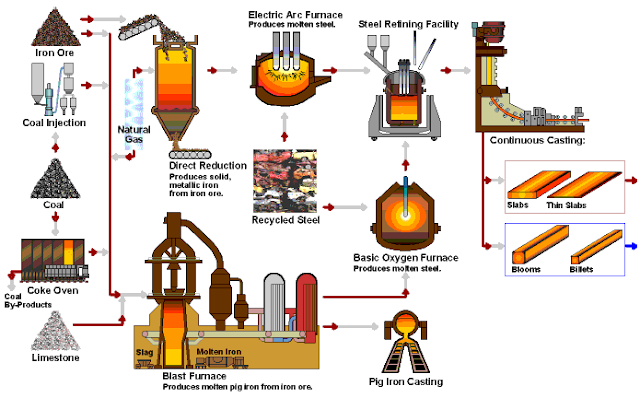

Ladle Refining Furnace Diagram

Ladle refining furnace multi-effect refining agent (auxiliary slag-making material) is applied to the molten steel refining process technology of foaming white slag in the reducing (or weakly oxidizing) atmosphere of refining slag. It is a low-cost smelting high-quality steel grade. The invention relates to a steel-making method, which belongs to the field of refining outside the molten steel furnace.

Ladle refining furnace, namely LF furnace (LADLE FURNACE), is the main refining equipment outside the furnace in steel production. Its main tasks are:

①Desulfurization

②Temperature adjustment

③ Precise fine-tuning of ingredients

④Improve the purity of molten steel

⑤ Slag making.

With the increasing demand of users for high-grade steel, especially clean steel with low nitrogen, hydrogen, phosphorus, sulfur, oxygen, and low inclusions, such as X65 anti-H2S submarine line pipe steel, X52QS anti-strong acid ultra-low sulfur line pipe steel, CS-110SS anti-corrosion oil casing steel, WB36CN1 nuclear power pipe steel, etc. These high-quality products have high requirements on the mass fraction of nitrogen and hydrogen in the steel, which are difficult to achieve by conventional ladle refining furnace refining technology.

The steel-making method of a ladle refining furnace includes the following steps:

1. Transfer the initial molten steel of the converter to the ladle refining furnace, start the electric heating at the refining station and add the slag for about 3 to 5 minutes, depending on the steel type, the converter endpoint [C], and the amount of slag. , according to the ratio of adding 0.25~0.5kg per ton of molten steel, a multi-effect refining agent is added at one time;

Described multi-effect refining agent, is prepared from the component that contains the following percentage by weight: CaC2--45~70%, SiC-5~20%, Al-5~15%, and slow release agent 10~20%.

2. In the refining process, adjust the slag according to the slag change situation; if the thickness of the slag foam can not be completely submerged arc or poor deoxidation, then add a multi-effect refining agent to adjust the slag, and add 0.05 to 0.20kg per ton of molten steel each time. The proportion of slag was added to adjust the slag. When the thickness of the slag foam cannot be completely submerged, the N and H2O in the air are dissociated into N and H atoms that are easily dissolved in the molten steel by the arc, resulting in a dramatic increase in the [N] and [H] content of the molten steel, which directly leads to the intrinsic quality and performance of use are degraded or deteriorated. When the deoxidation of the slag is poor, it is difficult to realize the metallurgical function of reducing the content of molten steel [0] through the diffusion deoxidation of the slag, which also leads to a decrease in the intrinsic quality and performance of the steel.

3. 5~10 minutes before the end of the ladle refining furnace refining, add 5~Mkg/furnace bauxite or ferrosilicon powder or silicon calcium powder to break the slag, eliminate the CaC2 particles in the slag, increase the surface tension of the slag Promote the separation of steel and slag; at the same time, it can prevent slag inclusion in molten steel and promote the absorption of inclusions in molten steel by refining slag, and avoid carbonization of molten steel during vacuum treatment such as VD furnaces.

In the refining process, if the slag turns from white to gray-black carbide slag phenomenon, then add 5~15kg/furnace bauxite or ferrosilicon powder or silicon calcium powder to adjust the slag, and strengthen the ladle bottom blowing Ar stirring, to Maintain the foaming of the slag completely submerged arc and the stability of the white slag.

The chemical composition of the multi-effect refining agent is Ca-28~55%, A1-5~15%, C-15~30%, Si-3~15%, and slow release agent 10~20%.

Sustained release agents are oxides that significantly increase slag viscosity and surface tension and inhibit gas escape. Such as active BaO, CaO, MgO, etc.

During the specific operation, firstly, according to the oxygen content of the primary slag (FeO+MnO, etc.), the deoxidation ability of the deoxidizing elements, the gas generation amount of CaC2 and SiC, the requirements for the mineral phase composition of the white slag, the influence on the viscosity and surface tension of the slag Calculating the dosage of each deoxidizing element and corresponding components, that is, determining the specific weight percentage of each component of the multi-effect refining agent.

In order to effectively control the reaction speed of each foaming element, the generated gas sources C02 and CO (mainly CO) are sealed in the slag with high viscosity and surface tension for a long time. The particle size of the material can achieve a certain effect; second, by adding a slow-release agent that inhibits the foaming speed and gas escape, the viscosity and surface tension of the slag can be increased stably (the effect does not change much with temperature).

The best block degree or particle size range is: the ladle refining furnace multi-effect refining agent components are prepared, first each component is processed according to the following block degree or particle size requirements: CaC is 5~20mm, SiC is ≥ 3mm, Al is 1 ~5mm, slow-release agent≤5mm, then mix according to the design ratio and adopt the double-layer moisture-proof packaging of inner plastic and outer weaving, and the weight is advisable with 5 ~ 10kg/bag. Shelf life does not exceed 15 days.

Free send inquiries to stella@hanrm.com or inquiry99@hanmetallurgy.com if any needs.

Email: stella@hanrm.com Or stellarollingmill@gmail.com inquiry99@hanmetallurgy.com

Whatsapp/Wechat:+8615877652925

Website: https://www.hanmetallurgy.com/

.jpg)

没有评论:

发表评论